The FreeTwinEV project aims to develop digital twins for lithium-ion battery systems that can accurately represent their electrical and thermal behavior while remaining suitable for efficient numerical simulation. Such digital twins are an important tool for understanding battery behavior, supporting design decisions, and enabling advanced simulation-based development workflows.

A key part of this effort is the development of battery models at different levels of detail. High-fidelity three-dimensional electro-thermal models can describe the underlying physical processes with high accuracy, but their computational cost limits their practical use. These detailed models can therefore be reduced to hybrid reduced-order electro-thermal models that retain essential physical behavior while enabling fast simulation.

Experimental data is required to support this modeling workflow. Measurements performed on a real battery module provide a reference for validating simulation results and for tuning selected model parameters so that simulated behavior matches reality under defined operating conditions.

For this purpose, a compact battery module consisting of four lithium-ion cells connected in parallel (1S4P configuration) was designed and experimentally investigated. The dataset presented here documents these measurements and provides the experimental basis for validating electro-thermal simulation models and supporting their subsequent optimization within the FreeTwinEV digital twin framework.

This document provides a detailed description of the dataset published on Zenodo, where all referenced measurement data and technical documentation are stored.

Battery module and measurement concept

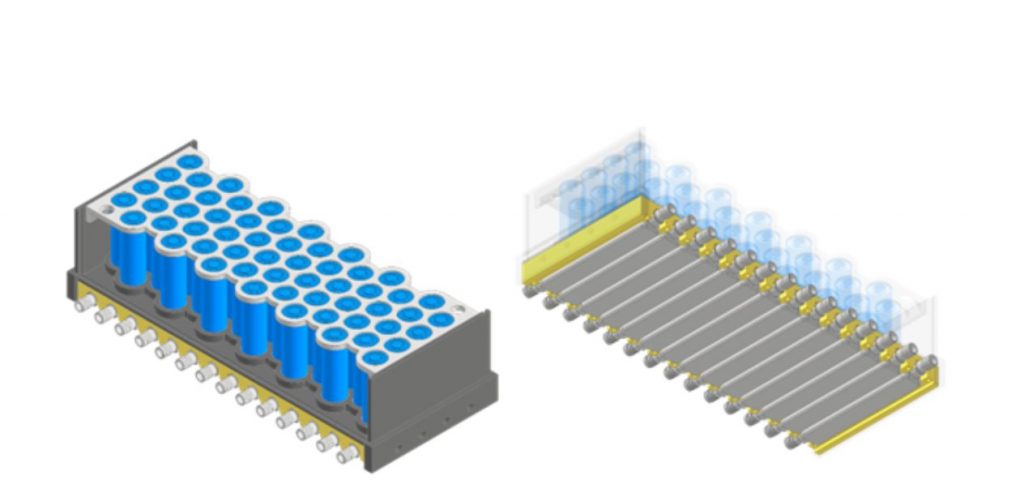

The investigated battery module consists of four cylindrical lithium-ion cells placed on an aluminum cooling plate with an integrated liquid cooling channel. The cooling concept is designed to remove heat through the cell bases and to limit temperature differences between individual cells during operation.

The 1s4p configuration represents a single series unit of the final battery module developed within the FreeTwinEV project. As such, the investigated module can be understood as a scaled-down representation of the final system, while preserving the key electro-thermal mechanisms relevant at module level. This approach allows detailed observation of module behavior, parameter tuning, and assessment of thermal performance before extending the concept to the full battery module. The whole module with 14 series-connected units can be seen in Fig. 1.

Fig. 1: FreeTwinEV battery module concept

The module layout was selected to support the development of a one-dimensional electro-thermal network model, with particular focus on axial heat transfer from the battery cells into the aluminum cooling plate and subsequent heat removal by the liquid coolant. The module on which the measurements were conducted can be seen in the figure below (Fig. 2)

Fig. 2: 1s4p tested module 3D model on the left and physcial model on the right

Experimental setup and instrumentation

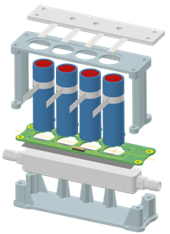

The battery module was instrumented with a comprehensive set of sensors to capture the relevant electrical and thermal quantities. The following sensor groups were employed:

- Cell temperature sensors – three sensors mounted directly on the surfaces of the individual battery cells along its axial axis,

- Cooling plate temperature sensors – ten sensors were placed on top of the aluminum plate to capture spatial temperature gradients,

- Coolant temperature sensors – one for measuring inlet and one for outlet temperatures of the cooling circuit,

- Ambient temperature sensor – one sensor recording laboratory environmental conditions.

All sensor locations, sensor names, and corresponding data acquisition channels are documented in detail in the Sensor_Layout worksheet of the laboratory measurement protocol and can be seen in the figure below (Fig. 3).

Fig. 3: Sensor layout within the battery module

Electrical quantities, including module current, module voltage, and state of charge (SOC), were recorded synchronously with the thermal measurements. The coolant flow rate was monitored to ensure stable and well-defined convective boundary conditions.

Measurement procedure

The measurements followed a predefined laboratory measurement protocol, which specifies the complete sequence of operating steps, stabilization periods, and transitions between test phases. To avoid redundancy, the detailed step-by-step procedure is not reproduced here and is instead fully documented in the Measurement_protocol.xlsx file included in the dataset.

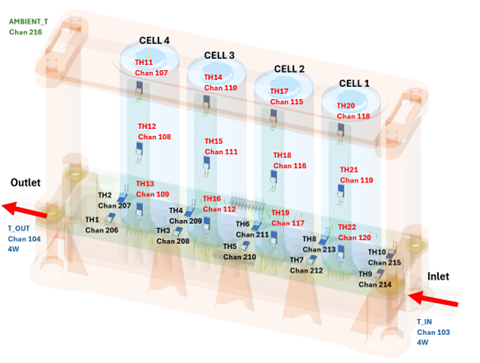

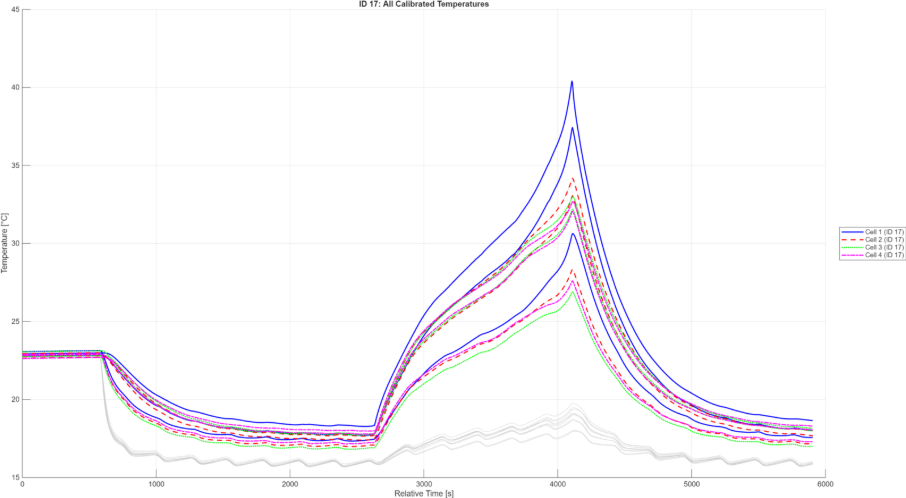

An overview of all performed measurements and their associated test conditions is provided in the Test_Matrix worksheet of the protocol. In total, 14 individual measurements were conducted, each corresponding to a distinct combination of electrical loading and thermal boundary conditions. The measurement profile for ID 17 is shown in Fig. 4.

Fig. 4: Temperature profiles of all four cells for measurement ID 17

Dataset description and structure

The experimental data are organized into a structured dataset suitable for direct use in modeling and simulation workflows.

Each measurement is stored in a dedicated subdirectory labeled with a unique measurement identifier and a timestamp generated by the data acquisition system. For each measurement, the recorded data are provided in both .csv and .xlsx formats, containing identical content to ensure compatibility with different analysis environments.

The recorded time-series data include:

- timestamp [s] – Timestamp,

- current [A] – Battery module current,

- voltage [V] – Battery module voltage,

- SOC [%] – State of charge,

- liquid_flow [L/min] – Coolant flow rate,

- temp_ambient [K] – Ambient temperature,

- temp_inlet [K] – Coolant inlet temperature,

- temp_outlet [K] – Coolant outlet temperature,

- temp_TH1-TH10 – Temperature measurements from 10 cooling plate temperature sensors,

- temp_cell-1_TH20-TH22 – Temperature measurements from 3 temperature sensors placed on battery cell number 1,

- temp_cell-2_TH17-TH19 – Temperature measurements from 3 temperature sensors placed on battery cell number 2,

- temp_cell-3_TH14-TH16 – Temperature measurements from 3 temperature sensors placed on battery cell number 3,

- temp_cell-4_TH11-TH13 – Temperature measurements from 3 temperature sensors placed on battery cell number 4,

All variable names, sensor identifiers, and channel mappings are consistently defined and traceable through the accompanying measurement protocol.

Intended use and scope

The dataset is intended as a technical reference dataset for the development, calibration, and validation of reduced-order electro-thermal models and digital twins of battery modules. While the measurements were performed under controlled laboratory conditions, the data capture the dominant physical phenomena required for constructing accurate virtual representations of the investigated system.

Interpretation of the results and model development based on the dataset are beyond the scope of this documentation. The presented measurements are intended to support the development of electro-thermal models that, once properly calibrated, can reproduce measured behavior and provide meaningful predictions beyond the tested operating conditions.

Reference

[1] M. Plzák, Š. Berta, A. Ürge, and M. Baťa, 1s4p Battery Module Measurement, Zenodo, Jan. 28, 2026. doi: 10.5281/zenodo.18405243.